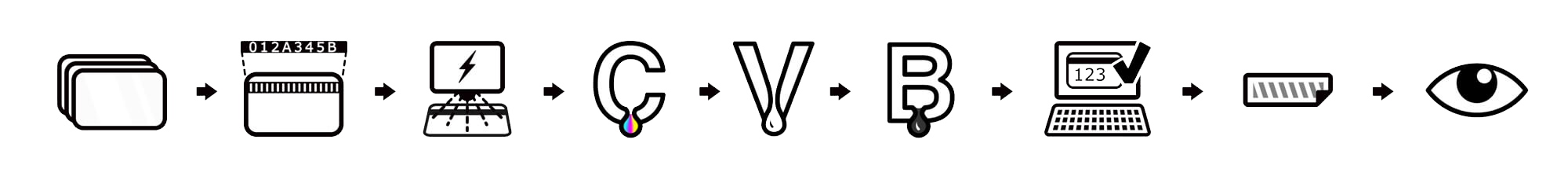

HOW IT WORKS

From a blank white card to fully designed, store-front ready product all on one machine!

Card Stock

We start out our process by loading our “Feeder” with the blank card-stock that you have selected for your order. It is important to select the proper card-stock that will give your product that WOW appeal you are looking for. There are 2 main types of cards we use for production, and that is Matte and Silk stocks. For more information on our various card stock options, please head over “here” or give us a shout and we will be happy to help you out. Once the feeder is loaded and the machine started up, the feeder will control the speed at which the cards fall onto the belt, usually based on a percentage of the belt speed.

LEARN MORE

Encoding

Once the cards are on the belt, the first process they reach is the encoding. If your card has a magnetic stripe on it, this is where we will encode the data onto your card. Encoding is a very complex and detailed procedure, which is what makes it great for security. We will not bore you with all the specifications and details involved in encoding, however, if you would like to know more about how it works, feel free to contact us. If you are not sure what type of magnetic stripe you need, or how it is supposed to be encoded, we will be more than happy to help you out!

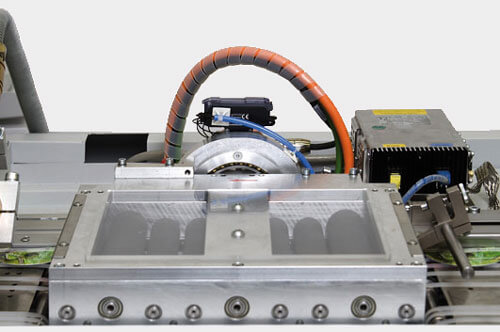

ORDER NOWPlasma Treatment

Next on the line comes the Plasma Treatment. There are 2 sections for this, once here for the front of the card, and again after the varnish for the back. What this does is prepare the card surface for the ink to adhere to it. Without the plasma treatment, your card would look like it was printed on a piece of wood with all the lines that would result. Our machine uses what is called a “retinal nozzle”, which means that it spins around in a circle and is able to hit the entire surface of the card, as opposed to a normal “jet nozzle”, which applies the plasma in only a small section.

ORDER NOW

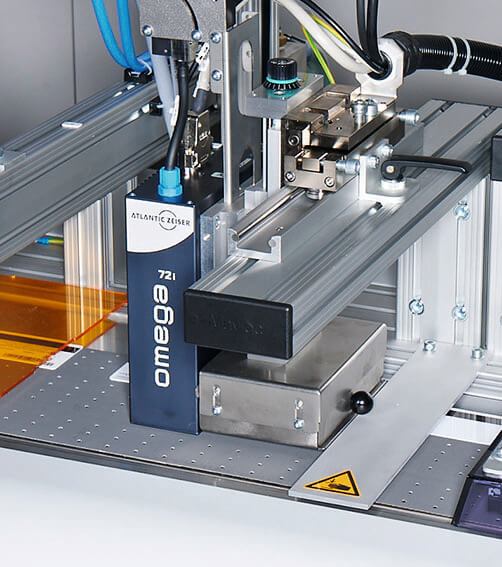

Colour Print

Finally, we get to the exciting part, the colour printing. This is where we take your blank white card and turn it into your personalized product! Our colour head prints using CMYK (Cyan, Magenta, Yellow and Black respectively), however, it prints in the order of KCMY, so that the darker colours do not overpower the lighter Magenta and Cyan during the printing process. In between each colour is a small “Pinning Unit” that will ever so slightly dry the ink so that it does not spread around too much, but is still able to mix together. Our machine is able to print fully variable, full-colour fronts at up to 15 metres/minute, with a stunning resolution of 360 dpi. It certainly is a sight to behold and is revolutionizing the card printing industry.

ORDER NOWVarnish

After printing the colour, the cards move to the varnish stage. This is when we get to apply the finishing touches to the front of your card. Varnish is basically a clear-coat that is applied to the front of your card adding an extra layer of protection, but also creating a smooth, reflective finish. There are 3 different varnish options that you can use to finish your card with. Full (covers the entire front with varnish, Spot (only applies varnish to certain sections of the front) and None (no varnish is printed at all). There are different times where each option will be the preferred choice, for more information on this, please visit our Varnish Options page.

LEARN MORE

Black

The back of the card is generally not too exciting, although it often holds a lot of crucial information for your customers, such as legal information and personalized information (i.e. card numbers). Once the card has the varnish applied and is automatically flipped over, we are able to print your backs. Individual card personalisation is done here at up to speeds of 18 metres/minute.

ORDER NOWDigital Vertification

Throughout this process, there are MANY digital verifications that are completed automatically by the machine. From making sure that no products are too long or too short, to making sure the correct data that was encoded way back at the start, to matching what is printed on the black printer. One of these verifications are actual pictures that are taken of the card, which are then analyzed and compared to what our data file is telling the machine to print. This allows us to ensure that you will never receive a card for “Sally’s Hair”, but have the data for “Joe’s Pizza”. Should the machine encounter an issue, it will reject that card and immediately print it again with proper information.

ORDER NOW

Labeller

Once your back is printed you have the option of having a label applied to the back of your card. Whether it is a scratch-off label to cover a PIN number or an activation label, it will go through the same process. All cards within a particular order have to have the same type and position of the label as these are not variable options during production.

ORDER NOWManual Inspection

Here at Quickcards we strongly believe in delivering only the highest quality product possible. That is why we inspect the front of each and every card that comes off our machine. Our operators are looking for and pulling out anything that isn’t perfect, be it a stray piece of lint, a line in the print, or even a poor alignment with the varnish. This method of inspection is significantly better than just doing spot-checks, as you can avoid the unpleasantness that is opening a pack only to find out 4 or 5 cards down you lose the quality you saw on the first card!

ORDER NOW

Request a Tour!

If you would like to see this process in action, please let us know and we can schedule a time for you to come and see it running! We would be happy to show you the ropes and even send you home with a “goodie bag” of samples.

Request

- Blog

- 866.610.3073 Ext 134

- Email Us

Reseller Program

Reseller Program Terms & Conditions

Terms & Conditions

A Division of ALLCARD LIMITED | 765 Boxwood Drive, Cambridge, ON N3E 1A4 | allcard.ca